Deanna Mudie, Senior Principal Engineer, Research and Development, Ryan Littich, Head of Advanced Chemistry Technologies, Research and Development, and Aditya Kaushal, Director of Bioavailability, pose the question: what tools are available to help a molecule progress through the early stages of discovery more smoothly and reach commercialisation sooner?

Fixing solubility problems

An issue that has dogged pharmaceutical development in recent years is the increasing proportion of small molecules entering the pipeline that have very poor solubility.

This is a problem as poor solubility leads to low bioavailability. But, if it’s addressed at the outset, then there are ways to mitigate it. A key tool here is solid form screening.

As a bridge between drug substance and drug product, its aim is to identify the optimal solid form. This will often be a crystal polymorph, but that’s not the only possibility.

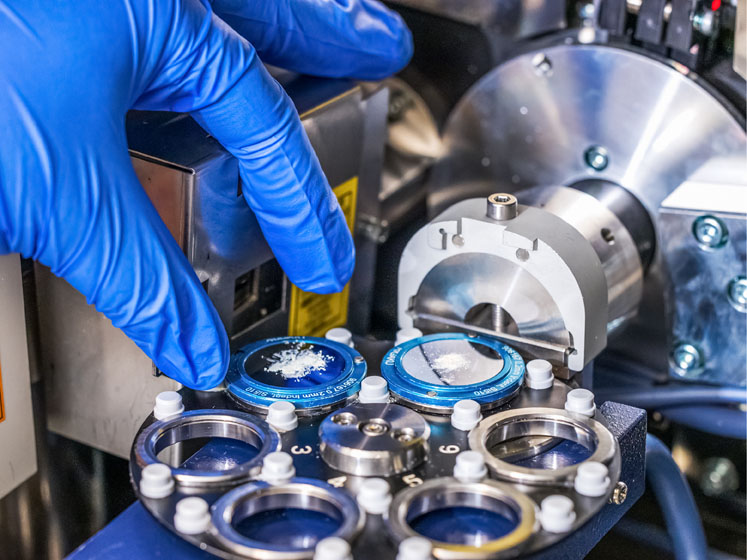

When determining the crystallisation process, it is important to consider the yield, the particle size and the impurity profile, as well as how the crystals will behave during formulation.

For example, will they be stable during storage and/or compatible with excipients? And, importantly, they need to be sufficiently soluble to achieve the required bioavailability.

Many molecules can exist in multiple different crystal forms … and some of these are likely to be more soluble than others.

So, if a more soluble form can be identified, manufactured consistently and not convert to another form during storage, this might be the ideal option to progress with.

If there is no obvious candidate, then the solid form screening process can look for alternatives. A solvate form might prove to be more soluble, for example. If the molecule is ionisable, then the answer may lie in forming a salt.

If not, a cocrystal might be an option. If all else fails, then an amorphous form might be the way ahead. Selecting the most suitable form will always be a critical part of a drug’s early development.

It needs to balance stability, manufacturability and in vivo performance; but, if this is done carefully and effectively, then the result should be a solid form that will enable seamless progression of the molecule.

And, with an efficient solid form screen, there will also be time and cost advantages too. Here at Lonza, our solid form screening workflow starts with the careful characterisation of the active pharmaceutical ingredient (API) ahead of a survey of crystal forms; this typically takes 3–4 weeks and requires 2–5 g of material.

Then, if necessary, further screening of potential salts or cocrystals can be done or an amorphous form developed.

Absorption predictions

Physiologically based pharmacokinetic (PBPK) modelling is a powerful tool that can be used to gain an understanding of how a candidate drug might behave in vivo, particularly regarding its absorption characteristics.

Many in vitro methodologies have, in the past, been used to predict human oral absorption; they have certain drawbacks, however, such as an inability to cover the whole scope of the absorption process and challenges in terms of extrapolating the results of animal studies to humans.

PBPK modelling is a mathematical tool that describes a compound’s molecular properties and physiological parameters (animal and human), and has recently gained significant attention in the pharmaceutical development world.

In combination with in vitro assays, the tool enables bioavailability and plasma exposures to be predicted far more effectively. It can also help to predict how interactions with other drugs or food effects might affect its performance.

These insights can then be used to determine the optimal solid form and dosage form for an individual molecule to maximise its in vivo performance. They can also be used to mitigate predicted problems, such as those caused by low solubility and bioavailability.

As well as looking for the ideal crystal, salt or cocrystal form, the answer may lie in an amorphous solid dispersion or a micronised form whereby smaller particles might dissolve more effectively.

Lonza uses ADMET Predictor® and GastroPlus® software in combination with a variety of both bespoke and off-the-shelf lab tests in its PBPK modelling service. PBPK modelling is an extremely useful tool that can predict problems in advance; and, if the answer is in place early, it can minimise delays and assist with meeting accelerated timelines.

Route scouting

As promising candidates move from discovery to development, process chemists work to design and deliver API synthesis routes that meet the pinnacles of safety, efficiency, reliability, quality and economy.

They strive to establish direct manufacturing paths that reliably deliver high product yields and purity while developing a deep understanding of each process step. They optimise each stage to extract the best productivity from available manufacturing assets.

Lengthy synthetic pathways, expensive starting materials, difficult-at-scale purifications and hazardous reagents are avoided. To ensure that patients have timely and economical access to promising new therapies, these considerations are front-of-mind for process chemists.

Although the tenets of an ideal API manufacturing process are longstanding, the molecular complexity of APIs has been steadily rising.

For example, the average length of a clinical-stage synthesis was approximately eight steps in 2006; today, chemists routinely encounter APIs with medicinal chemistry preparations of more than 20 steps.

And, in 2019, the lengthiest (disclosed) small molecule synthesis to date that progressed to clinical trials comprised 92 steps.

Increasingly step-intensive processes are challenging process chemists’ access to manufacturing ideals, creating significant supply chain complexities — and, as a result, impacting development start-up times.

Pharmaceutical and cheminformatics technology companies have developed computer-aided synthesis planning tools (CSPTs) to help mitigate the impacts of rising complexity.

CSPTs, given a molecule target, compute the shortest and highest probability-of-success retrosynthetic path to accessible starting materials. Lonza, by leveraging vast proprietary supply chain data in a leading CSPT, tailored its performance to uniquely address the challenges faced by process chemists in preclinical route design.

Today, our chemical synthesis experts leverage AI- and Lonza IP-enabled predictive and analytical informatics to devise and prioritise optimal synthetic pathways for development and manufacturing success.

Our enabling “chemmercial” informatics tools are already having an impact on timelines. Higher incidences of shorter routes are observed.

Lonza’s unique supply chain insights are empowering our SMEs to make real-time decisions about synthesis strategies, taking into account raw material costs, supply chain risks and chemistry considerations.

In summary

These are just three examples of the tools that Lonza routinely employs when working on an early stage drug development project. In combination with our in-house expertise and the insights provided by our track record of successful projects, they make a huge difference to the speed at which a potential new drug can be pushed through the development pipeline.

Bibliography

- R. Dach, et al., “Eight Criteria Defining a Good Chemical Manufacturing Process,” Org. Process. Res. Dev. 16, 697−1706 (2012).

- J.S. Carey, et al., “Analysis of the Reactions Used for the Preparation of Drug Candidate Molecules,” Org. Biomol. Chem. 4, 2337–2347 (2006).

- M.D. Eastgate, M.A. Schmidt and K.R. Fandrick, “On the Design of Complex Drug Candidate Syntheses in the Pharmaceutical Industry,” Nat. Rev. Chem. 1, 1–16 (2017).

- S. Kawano, et al., “A landmark in Drug Discovery Based on Complex Natural Product Synthesis,” Sci. Rep. 9(AN8656), 1–9 (2019).