Extract Technology launched an innovative, energy efficient downflow booth at Achema, providing a new energy saving way of dispensing powders. The new booth line engaged a lot of interest and discussion in Frankfurt, especially the show-only version with see-through side walls that are now considered an actual bespoke design option.

The product name – Greenline – stresses the main objectives of the innovation. New booth was designed to cope with the problem of noise pollution in labs and to support the worldwide efforts in limiting energy consumption.

EECO2, an energy efficiency consultancy, was commissioned by Extract Technology to monitor the company's new range of Greenline Extract Booths to independently validate performance. EECO2 has developed Mobile Energy Monitoring Units (MEMU), which are customised to suit the needs of Extract Technology’s booth including monitoring of:

- Fan power

- Lighting/controls

- Filter pressure

- Fan pressure

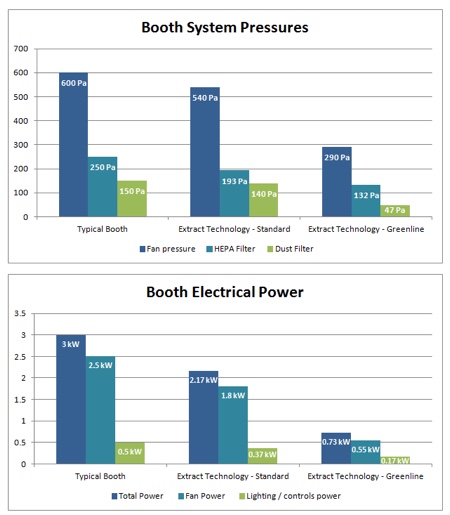

EECO2 engineers deployed the system on-site and took independent readings with calibrated equipment to verify the MEMU data. EECO2’s remote monitoring service allowed diagnostics and analysis of results. As can be seen from the charts, the Greenline booth has significantly reduced power and pressure requirements compared with standard booth systems.

Improvements recorded in booth system pressures and booth electrical power as shown below:

Extract has transferred the modular concept of the highly successful PharmAir booth into the GreenLine range of booths without compromising the flexibility, materials of construction or performance of the product. This innovative approach to the next generation of booth will offer clients the option to replace existing equipment with new equipment or simply upgrade existing equipment to benefit from the cost saving realised through the application of energy efficiency.

Key benefits:

- Guaranteed operator exposure levels of <100µg/m3

- LED Lightning

- Custom designed low pressure filters

- Auto standby/start mode

- Fans and motor fully compliant with ERP2015