A 650 kWh commercial demonstration unit with cloud dashboard and integration to a building management system was recently installed at the Alnwick facility of drug development and manufacturing accelerator, Quotient Sciences, with benefits to date including

- economic savings from charging with cheaper overnight electricity and from efficient trickle charging of the battery to replace inefficient chiller cycling

- continuity of operations under high temperatures humidity, when previously cooling demand could not be supported by existing systems

- resilience from always having cold energy stored on site — in case of core system failure or shutdown.

Stuart Munro, Head of Facilities at the Alnwick site, said: “Quotient Sciences is committed to reducing its carbon footprint and energy consumption at every opportunity. It is innovations such as the EnergiVault and engineers committed to change that our planet needs now.”

“The EnergiVault helped the business in a way we didn’t foresee. Last summer, one of the compressors went down in our chillers. We’ve got four compressors, so we were 25% down on cooling capacity."

"Had it not been for EnergiVault, that could have caused us some issues; we would have had to start restricting our cooling to some of the lab and office areas."

"But, because we had the redundancy of the EnergiVault in place, we started to pull down on that. The EnergiVault took the place of the broken compressor, while we waited for a replacement from Italy, and saw us through summer.”

“During the winter months, when cooling loads are lower, our compressors will run to a minimum of 25%. We can’t slow it down any more than that so we’re always going to be using that energy."

"So, instead of bringing that compressor on, EnergiVault is taking that small load for us during the day. If we don’t have to fire up our chillers and can use the EnergiVault instead, that should bring substantial savings.”

“If we have an off-peak tariff, we can charge up the EnergiVault at night and, during the day during the winter months, we don’t have to bring our chillers online at all. We are using this cheaper energy source that we charge up overnight and we’re drawing down on it throughout the day.”

“I was nervous at first about the EnergiVault coming in because this site is my responsibility and if we messed up the cooling it could bring down the business. But the communication has been great and there’s been zero negative impact to us. It’s been a positive experience and there’s more to come.’’

Bob Long, Executive Chairman and founder of O-Hx, said: “EnergiVault revelled in the high summer temperatures, displaying the ability to deliver huge amounts of thermal energy to support struggling cooling equipment.”

“The full-scale testing at Quotient Sciences delivered performance that surpassed our expectations many levels, including peak load support, resilience and reliability. With high confidence from this unit, commercialisation plans are now in place to be able to meet anticipated demand.’’

O-Hx Director David Grundy added: “It’s quite remarkable what we have achieved. At the start of 2022 we had a small proof-of-concept machine and a lot of desktop analysis."

"In the time since then we have raised £1 million in investment and used that to develop a full-scale commercial demonstration unit … which is working beyond our expectations. We have also completed our design-for-manufacture and developed a new storage tank that can hold more energy and discharge more quickly.”

“We are now ready to sell and install EnergiVault for commercial customers. Achieving this in such a short period of time, when product development normally takes many years and multiple millions, is testament to the quality of our team and the robustness of EnergiVault’s design. This is game-changing technology that will have applications around the world.”

Summary of results

Quotient Sciences required EnergiVault to support its systems in three of the four standard operating modes.

- Chiller optimisation: discharging to avoid inefficient chiller cycling.

- Peak demand support: discharging when existing systems are unable to cope with cooling demand or to replace existing chillers (for regular maintenance), with a range of instantaneous load support.

- Uninterruptible cooling: always retaining a proportion of available stored energy to cover any unforeseen chiller outages.

The fourth operating mode — load-shifting — has been tested via full charge-discharge routines but not directly tested on an operational basis owing to Quotient’s operating requirements and tariff structures.

EnergiVault performance

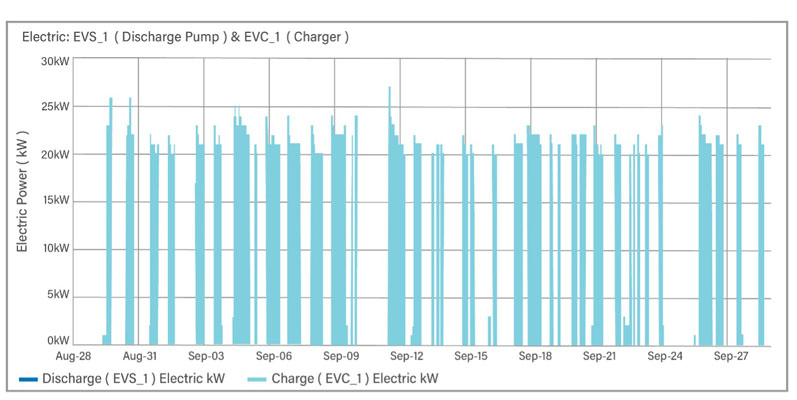

EnergiVault has been tested at various charging rates. To illustrate daily performance, Figure 1 shows electrical input to the charger for the 4-week period between 28 August and 24 September 2023, showing speed and duration of charge.

Figure 1: Speed and duration of charge for a 4-week period

Charge rates were consistent throughout the period, with an average electricity input of 20 kW. This low-input charge capability gives EnergiVault a significant advantage compared with on-demand chillers, which typically require much higher electrical inputs to deliver similar performance (Figure 2).

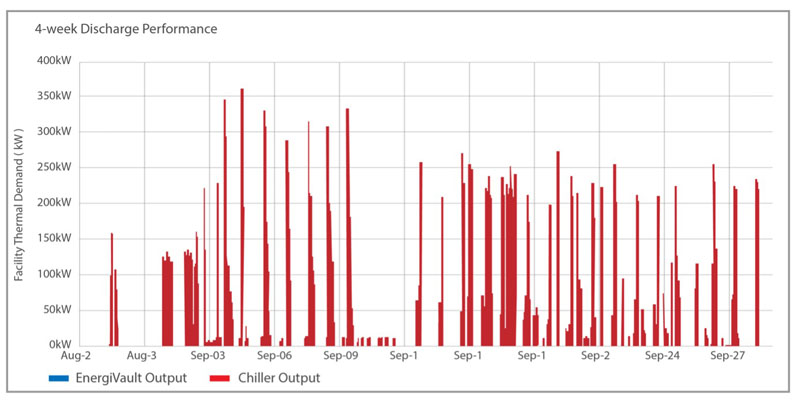

Differences in charge duration reflect the demands placed on the battery and depend on the amount of cooling support provided to the building at any given time (Figure 3).

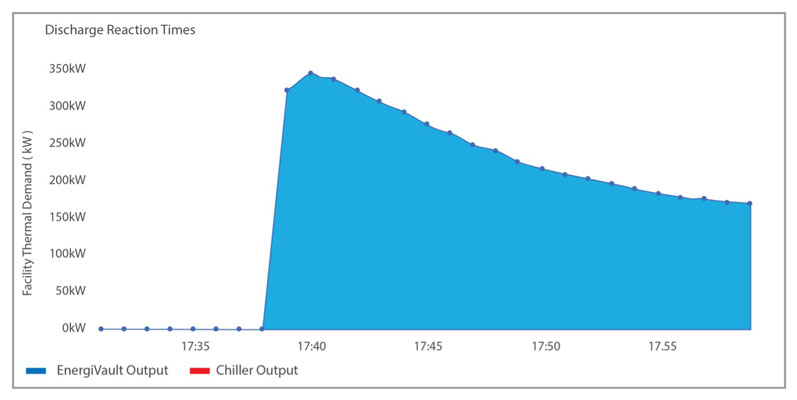

This ranged from an instantaneous 350 kW load, when the building’s chiller system could not meet demand or a chiller failure had occurred, to 10 kW discharge rates supporting chiller optimisation and preventing additional chiller cycling.

Figure 2: An illustrative 30-minute window from the Customer Dashboard, with peak discharge rate achieved after minute 2 of instruction to discharge

Figure 3: This graph mirrors the charger performance above, showing rate of battery discharge during a 4-week period

Illustrative operating modes and optimisation

As noted previously, EnergiVault has four typical modes of operation. Each have the same characteristic of delinking energy supply away from energy demand; the different profiles simply reflect different rates and duration of discharge. Choice of modes is influenced by

- Economic and carbon returns: charging in times of low-cost or low-carbon electrical supply, discharging to avoid high-cost or high-carbon supply — typically characterised by load-shifting and chiller optimisation modes

- Operational resilience: providing a store of energy to ensure operations can continue unhindered during periods of insufficient supply from core systems (breakdown, maintenance, inadequate capacity); can also be used as a supplementary chiller, with low electrical input, when incoming site supply is inadequate — typically characterised by peak demand support and uninterruptible cooling modes.

Each of the modes of operation, apart from load-shifting, was applied during the test period.

EnergiVault: how it works

The patented EnergiVault system consists of a charger and thermal store, or battery, and can be used — on its own or in place of an additional unit — alongside an existing chilled water system.

As with a chiller added to meet increased peak cooling loads, it can reduce the risk of production or building shutdowns, whereas additional features such as time of use (ToU) shifting, chiller optimisation, heat recovery and energy monitoring can be applied across a site’s entire cooling plant.

By utilising artificial-led intelligence it can access the electricity supply at low tariffs and at periods of low carbon intensity.

The system’s ice crystalliser charges the battery by converting the heat transfer fluid (HTF), typically a water/glycol mix, into spherical ice crystals a fraction of a millimetre in diameter, each surrounded by a film of organic material.

This ice slurry acts as the phase change material (PCM), delivering a huge increase in the surface area on which the thermal transfer takes place.

Phase change batteries generally have the limitation of a low discharge rate because of the surface area to volume ratio and cannot always meet the required load.

By maintaining an ice slurry as its thermal store, EnergiVault significantly increases the range of energy transfer at any given time. Thermal energy batteries do not reduce in capacity with time and, therefore, avoid the resulting loss in energy capacity experienced by lithium-ion storage.

Most sites will have variable demand, with opportunities to deliver value across multiple operating modes and cost-effective variable tariffs. In these cases, the proprietary optimising software can unlock significant additional value.