Freeze drying is an established technology that the companies Biopharma Technology and Stabilitech have managed to move forward. With the aid of recent grants both companies have found new applications in biotech, reports Sarah Webster.

Freeze drying was actively developed during World War I, and has since been used as a preservation or processing technique for a wide variety of products, including pharmaceuticals, diagnostic kits and food. The freeze drying process ensures a product remains chemically stable and viable until rehydration, and equipment used is continually evolving to increase the efficiency and effectiveness of the freeze drying process.

Designing and developing successful freeze drying formulations and cycles requires a rational, knowledge-based approach to determine how a product will respond to different processing conditions and optimise the process accordingly.

Each stage of the process – freezing, primary drying and secondary drying – has its own challenges and requirements. There are a myriad of factors that will affect the product including the thermal characteristics and crystallisation behaviour of the formulation itself, the dimensions and materials of the container, concentration and desired final moisture content.

Other important factors to consider include the product’s collapse temperature (Tc) and glass transition temperature (Tg’). Tc is the temperature at which the material softens to the point of being unable to support its own structure, whereas Tg’ is the temperature at which the frozen material changes from a brittle to a flexible structure. Historically, it was believed that Tg’ and Tc occur at the same temperature. However, this is not always the case and the difference can be missed even with sensitive methods.

Biopharma has developed the Lyotherm2 to measure differential thermal analysis (DTA). This has enabled mobility increases to be identified below traditional critical temperatures.

Once analysis has been carried out a cycle can be developed to produce a product that has:

- A cosmetically acceptable cake

- Good stability

- Long shelf life

- High activity rate

- Low moisture

- Rapid rehydration

The technology is still being developed to this day with two UK-based freeze drying businesses, Biopharma and Stabilitech, carrying out new research that will benefit pharmaceutical manufacturers. Both companies were also recently awarded grants from the UK Technology Strategy Board (TSB) – a business-led executive non-departmental public body, established by the UK government to promote and support research and exploit technology. It is sponsored by the Department for Business, Innovation and Skills (BIS).

Biopharma has been pioneering innovations in the freeze drying field since 1997. The company has developed two flagship analytical instruments for freeze drying: the Lyostat freeze drying microscope and the Lyotherm DTA electrical resistance analyser. Over the past decade, these instruments have been honed to provide the latest generation of freeze drying apparatus – the Lyostat3 (see Figure 1) and the Lyotherm2 (see Figure 2).

Determining critical temperatures is fundamental to Biopharma’s intelligent freeze drying philosophy. Significantly, every formulation has a critical temperature; this is the temperature to which it should be cooled for complete solidification and maintained below during primary drying in order to prevent processing defects. Biopharma’s Lyostat3 freeze drying microscope is used to identify temperatures at which visible changes occur, together with relative drying rates.

Biopharma’s approach helps to minimise inefficiencies – for example, difficulties in scaling up the process leading to increased operating costs and delayed product launches. Biopharma has used this ‘intelligent freeze drying’ approach to analyse and develop efficient cycles for hundreds of samples, from small drug molecules to large complex bio-molecules for many companies worldwide.

probiotic study

Following the TSB grant, Biopharma worked in conjunction with biotechnology specialists Microbial Developments and the University of Cambridge on a study that looked at methods of improving the delivery of probiotic bacteria. The project was co-funded by the TSB through the ‘Developing High Value Chemicals Competition’ launched in 2010, which looked at funding projects investigating how industrial biotechnology could be competitively applied to the production of high value chemicals.

The project focused on three key areas: optimisation of fermentation methods; freeze drying formulation and procedure; and a gut delivery system. The aim was to produce stable L. crispatus in a format that can be reliably and efficiently delivered to the gut.

At the end of the six-month study, fermentation studies carried out by Microbial Developments had produced a 20% increase in the harvestable yield, Biopharma had designed a formulation and cycle that enabled the bacteria to be freeze dried with a less than 1 log reduction in viability, and reagents studied by the University of Cambridge showed promise in protecting the bacteria in the gut for up to 60 minutes, allowing rehydration and revival.

The results from these studies were combined to produce a complete ‘optimised product’ in capsule form, which will be subject to further investigation throughout 2011.

Stabilitech has developed a proprietary technology that can be used to stabilise vaccines and biopharmaceuticals, removing the need for refrigeration and protecting them from heat and freeze damage, as well as reducing losses during manufacture. The technology is based on a carefully selected combination of excipients, combined with freeze drying. Although the company has also started to work on liquid formulations, freeze drying is a core part of Stabilitech’s technology.

virus stabilization

Stabilitech has succeeded in mimicking the long term stability seen in certain seeds, using an entirely chemical combination of excipients, combined with lyophilisation to give high degrees of stabilisation to a wide range of products, particularly live viruses, which are highly fragile and a challenging target.

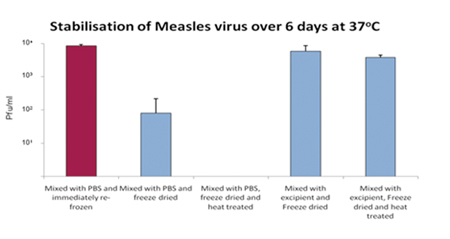

To demonstrate the company’s technology, Stabilitech’s founder, Dr Jeff Drew, turned initially to the measles vaccine, which is sold as a lyophilised live attenuated virus and which is highly thermally fragile. He found that Stabilitech’s combination of excipients, combined with lyophilisation, was able to stabilise the virus with minimal losses on freeze drying and then further very small losses following heat challenge at 37˚C for several days – in comparison with the major losses in similar conditions without Stabilitech’s excipients, as shown in Figure 3.

Figure 3: Stabilitech’s excipients combined with lyophilisation stabilised the measles virus with minimal losses on freeze drying and then further very small losses following heat challenge at 37˚C for several days – in comparison with the major losses in similar conditions without Stabilitech’s excipients

Freeze drying can be an aggressive process, removing water from protein solutions, including water at the protein surface, which plays a role in protein structure. Damage often ensues, with concomitant loss of potency.

Stabilitech theorises that the excipients displace the water at the surface of the protein, allowing the water to be removed by the lyophilisation process with less resulting damage to the protein. The sugar components of the excipient mixture may also then form an amorphous matrix, locking the proteins/viruses into a form of stasis.

Stabilitech has successfully stabilised a wide range of live viruses, including both enveloped viruses such as measles and Modified Vaccine Ankara, as well as non-enveloped viruses such as adenovirus, and also a wide variety of viruses important in animal health. The technology has also been applied to whole inactivated viruses and sub-unit vaccines.

Stabilitech was awarded a grant by the TSB as part of its competition on Detection and Identification of Infectious Agents: Fighting Infection through Detection. The company will apply its broadly applicable stabilisation technology to stabilise a range of antibodies and antibody conjugates against infectious disease, in order to enable storage and use of diagnostics at ambient and elevated temperatures. The grant is for a feasibility study of one year, towards which the Technology Strategy Board will provide up to £120,000.

Stabilitech is actively involved in the expansion of its Intellectual Property portfolio in addition to concentrating on its core business model. The company recently returned from participating in the Future Health Mission to the United States. The trade mission, sponsored by UK Trade and Investment (UKTI), the Technology Strategy Board (TSB), as well as some private organisations, selected 19 of the UK’s most exciting healthcare-related companies to participate in a trip to San Francisco during the week of the JP Morgan conference.

Stabilitech also received a US government contract in April 2010 from the Defense Threat Reduction Agency (DTRA, an agency within the US Department of Defense) to stabilise two vaccine candidates for biodefence use.