Having discussed mitigation strategies in Part I and taken a deep dive into critical aspects such as quality control and the supply chain, Part II addresses the equally important impacts of stability/shelf life, the need for comparability studies and regulatory considerations for CGT.

Stability/shelf life: As well as being complex and heterogeneous, CGT products are also susceptible to degradation. Patient-specific cell products are unique and, often, only one lot is prepared for each patient.

In general, the lots tend to be small volume, sometimes less than 10 mL, and they may involve products that cannot be frozen. As such, they have short shelf-lives (24–72 h) as the cells continue to metabolise their medium.

Early forced degradation studies under a range of accelerated conditions are recommended to understand the degradation mechanisms for the viral vectors.

Developing innovative formulation strategies by optimising the excipients/buffers will be critical to minimising the rate of degradation. This will provide a longer shelf-life for the finished product and possibly enable storage under refrigerated conditions for shipping and handling.

Comparability: Inevitable changes in CGT development necessitate comparability studies to ensure data leverage and continuity despite the modifications.

Type-specific comparability studies encompass changes in raw materials, formulation, manufacturing process, facility or site, analytical methods and regulatory compliance-driven alterations.

The strategy involves defining the change type, conducting risk assessments, identifying critical quality attributes (CQAs) and critical process parameters (CPPs), selecting suitable analytical methods, and sharing the comparability protocol with regulatory agencies for preapproval.

Regulatory frameworks and compliance considerations

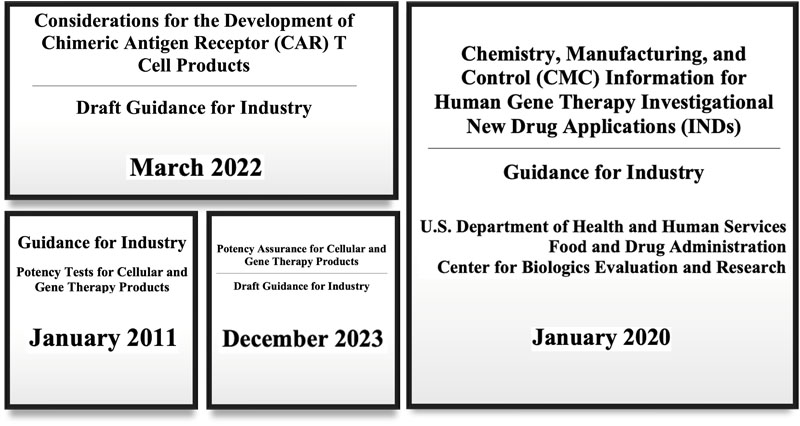

Key recommendations for CGT products are found in several regulatory guidelines (Figure 2). Notably, the 2011 Potency Tests for Cellular and Gene Therapy Products guidance on potency assays for all CGT modalities was recently updated (December 2023).1,2

Additionally, the 2020 CMC Information for Human Gene Therapy [Investigational New Drugs] INDs guidance remains pertinent as, at least in the United States, the ex vivo gene-modified cell therapies are technically gene therapies even though there is a cellular component in the final drug products.3

Furthermore, the 2022 draft guidance specific to CAR-T products provides comprehensive recommendations for preclinical, safety, efficacy and CMC development.4

Figure 2: Regulatory guidance for CGT development

Stringent adherence to regulatory guidelines is crucial for autologous therapies owing to their personalised development processes; meticulous documentation and data management practices are imperative.

Allogeneic therapies necessitate robust comparability studies and comprehensive product characterisation to ensure consistent safety and efficacy profiles throughout diverse patient populations, requiring strict regulatory oversight.

Potency assay development and validation play a pivotal role in demonstrating the therapeutic effectiveness of CGT products, with regulatory agencies emphasising their importance in the approval process.

Seeking early US Food and Drug Administration (FDA) feedback is crucial to navigate the initial development of such complex therapies.

Although pre-IND meetings can be used by CGT product sponsors to discuss CMC-specific issues, they can engage with the FDA even earlier through INTERACT, a new Center for Biologics Evaluation and Research initiative allowing for expanded discussions on CMC strategies as well as development plans and clinical considerations.

Examples of key CMC-specific topics that warrant attention during INTERACT and pre-IND meetings for CGTs include the following:

Raw material selection: Selecting quality raw materials is extremely important because slight variations can greatly impact CGT product quality. Early reliance on research-grade materials may complicate later phases.

Although some processes depend on animal- or human-derived materials, optimisation to exclude these is ideal. Ensuring high-grade compliant materials with proper regulatory documentation is vital. Discussing this topic with the FDA early can minimise late-stage process changes.

Establishing acceptance criteria: Understanding the product’s mechanism of action (MoA) is vital to define CQAs and CPPs. Consider using surrogate assays for additional insights if the MoA is unclear.

Seek FDA input regarding analytical methodologies early and their recommendation regarding additional attributes that should be evaluated and controlled. Leverage FDA’s product-specific knowledge based on their internal learnings from historical reviews to support specification development.

Addressing guidance discrepancies: Certain aspects of CGT development may not align with existing guidance, presenting challenges in terms of adhering to standard requirements. Discussing alternative solutions and control strategies with the FDA can help to address these gaps early.

Conclusion

The future of CGT CMC hinges on the development of advanced logistics and point-of-care processing capabilities for autologous therapies, as well as the establishment of standardised manufacturing protocols and scalable production platforms for allogeneic therapies.

Collaboration between industry stakeholders, academic institutions and regulatory bodies remains instrumental to drive the standardisation of best practices, fostering innovative research and ensuring the continued development of safe, effective and accessible CGTs for patients worldwide.

References

- www.fda.gov/media/79856/download.

- www.fda.gov/regulatory-information/search-fda-guidance-documents/potency-assurance-cellular-and-gene-therapy-products.

- www.fda.gov/regulatory-information/search-fda-guidance-documents/chemistry-manufacturing-and-control-cmc-information-human-gene-therapy-investigational-new-drug.

- www.federalregister.gov/d/2022-05539.

Key CMC points to consider

- Hold early and timely discussions with regulatory agencies

- Develop relevant analytical procedures earlier in development

- Manage and document process changes

- Conduct ongoing and continuous process monitoring

- Retain samples for future comparability studies and analytical development

- Develop a due diligence, technology transfer and quality agreement

- Ensure good co-ordination and communication between all stakeholders

- Consider the shipping control strategy early in development

- Focus on manufacturing logistics and capacity

- Always keep patient safety in mind.