The established and widely recognised method for crystallography is X-ray diffraction, by which crystalline compounds in the micron size range are diffracted using an X-ray beam to study their structure. However, not all crystals are this “big.”

Many pharmaceutical companies struggle to structurally characterise their nanosized compounds. Crystallography mainly relies on diffraction techniques and the most recent of them, electron diffraction, is gaining increasing attention.

By using electron radiation, it is now possible to investigate nanosized solids with atomic resolution. By overcoming the crystal size limitation, electron diffraction allows investigations on nanocrystalline systems to be done and has the potential to become an analytical breakthrough that will drive innovation in a variety of fields; among the first to profit will undoubtedly be the pharmaceutical industry.

There are many acronyms used in the field of electron diffraction — such as ADT, EDT or microED — which refer to nanoscale experiments. They rely on exposing solid state material to electron beams and obtaining important structural information from nanosized particles.

The technique is disruptive and will have a massive impact on how research is done in the future. Concerning drug discovery alone, hundreds of thousands of known but not fully characterised crystalline compounds could be rapidly screened for their scientific or commercial potential.

Moreover, there are many other fields in inorganic and organic chemistry in which an improved investigation technique would stir up the status quo, among which are agrochemistry, batteries and metal organic frameworks.

Author Eric Hovestreydt, ELDICO Scientific

Apart from the sheer number of compounds that are unmeasurable because of their size, every Big Pharma company has to meet stringent criteria to bring a candidate through the drug development process. For example, to develop and authorise a new active pharmaceutical ingredient (API), every possible drug candidate must be fully characterised and tested for polymorphs.

These studies are mainly done using X-ray powder diffraction (XRPD) and, for such experiments, the scientist needs at least a few milligrams of sample for each test (dissolution, slurries, temperature dependence, etc.). With electron diffraction, only a few particles are needed.

In a batch that might only contain “one” polymorph, other polymorphic forms might sometimes go unnoticed because of the detection limit of the equipment used. Such examples require high-resolution/high-quality XRPD synchrotron measurements at large research facilities, where measurement slots are a scarce resource.

In an electron diffraction experiment, however, nanopowders are sufficient — a structure can be obtained directly “from the flask” (as the only prerequisite is that the material must be crystalline).

Nowadays, such electron diffraction experiments are done on “non-native” instrumentation, such as TEMs — which offer limited data quality as they are designed for purposes other than diffraction and, as such, are often retrofitted for electron diffraction using hard- and/or software add-ons.

Dedicated instrumentation, which means that it’s specifically designed to run electron diffraction experiments, is able to deliver important structural information faster and, more often than not, proves to be the best approach in terms of efficiency, quality of data and time spent.

With the proper instrumentation for electron diffraction, many more labs may soon be able to perform routine analyses on samples that have so far been considered prohibitive, including nanocrystalline powders, minute quantities and phase mixtures.

The value proposition of electron diffraction for the pharma industry is a fuller pipeline of APIs for the drug development process. Pharmaceutical companies can get an accurate characterisation of preclinical candidates to confirm their functionality as a potential drug.

This ensures earlier market adoption and savings of up to $5 million and 6 months for one API —equating to billions of saved dollars in lead discovery for the industry as electron diffraction experiments produce high-quality structural information directly in the nanocrystal regime.

The coronavirus pandemic and the rush to find an effective vaccine is a prime example. Although vaccines seem to be the most promising way out of the dire pandemic situation, clinical research and approval can be a long and complicated process. Take, for example, HIV, which has been studied for more than 30 years without an effective vaccine being discovered. Yet, with the help of small molecule drugs, living with the virus has become manageable.

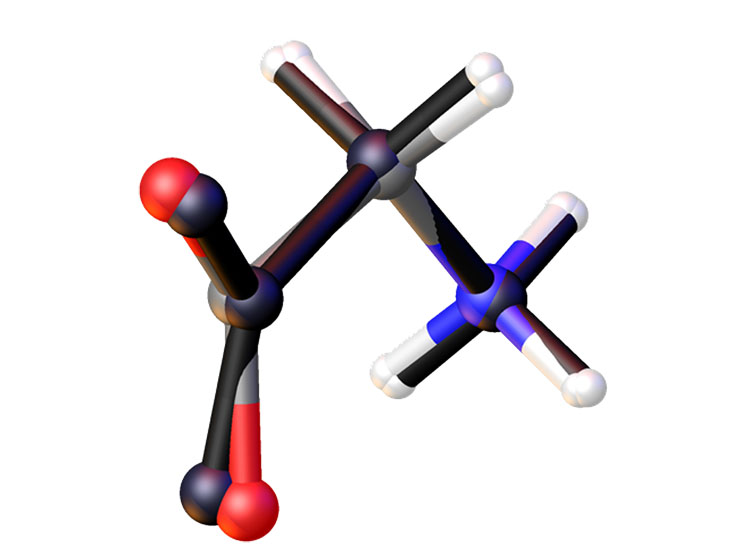

Small molecules (those that only have a few dozen atoms, as opposed to “large” ones that comprise hundreds or thousands of atoms) are popular alternatives in drug research, especially as they already account for approximately 90% of today’s medicines.

This is quite significant, given that the APIs in question represent such a diverse group of compounds that have nothing in common.1 What’s more, small molecules are both affordable and are well-known protagonists in many of the human body’s metabolic processes. However, designing and making new small molecule drugs can be quite a long and tedious process.

So, what’s the solution? Fragment-based drug discovery (FBDD, also known as fragment-based lead discovery [FBLD]), as Daniel Erlanson elucidates in “Many Small Steps Towards a COVID-19 Drug,” is definitely is one of the most promising ones.2

Instead of screening hundreds of thousands of large drugs, FBDD uses limited libraries of existing fragments to more efficiently find the most attractive starting points for medicinal chemistry.

This major trend in drug development accounts for nearly 50 FBDD-derived drugs that have already entered clinical development.

To guarantee the success of FBDD, fragments need to have been characterised down to their atomic level, as typically done with X-ray diffraction, particularly for computational fragment-based approaches to further improve the identification of fragment hits.3

Nonetheless, to avoid the rate-limiting step of having to characterise crystals in the size range of hundreds of microns, the pendulum is swinging away from X-rays towards the use of electrons, thereby making it possible to determine the molecular structure of powders consisting of 10–1000 nm crystals.

It is perhaps surprising that, until now, there was no dedicated instrumentation for such a robust technique as electron diffraction. The ELDICO ED-1, the brand-new electron diffractometer from ELDICO Scientific is making a significant difference.

The instrument combines an optimally designed electron beam with a goniometer that’s precise down to the submicron level. In a class of its own, the ED-1 combines the best of two worlds, enabling diffraction experiments at the nanoscale in an easy-to-install, user-friendly device. Equipped with this instrument, any lab will be able to perform routine analyses on samples that have so far been considered prohibitive.

References

- https://xconomy.com/boston/2015/11/23/small-molecules-the-silent-majority-of-pharmaceutical-pipelines/.

- https://doi.org/10.1038/s41467-020-18710-3.

- www.sciencedirect.com/science/article/pii/S1359644620302518.