Traditionally, compressed air has had several shortcomings that impact drug manufacturing and handling, such as high maintenance costs, a significant risk of contamination and the presence of moisture. Compressed air quality in a pharmaceutical manufacturing process is directly related to end-product quality.

Previously, pharmaceutical companies were afforded the luxury of simply paying the additional price to ensure this quality. Nowadays, they need to balance the rising costs and energy emissions of the plant while, at the same time, maintaining product quality and process efficiency. This means that they’re now challenging existing norms and looking for innovative solutions to their quality compressed air needs.

In addition, reducing emissions and operational energy use is also a key concern for policy makers. In Europe, energy efficiency and the broader goal of carbon emission reductions is putting the manufacturing industries under further pressure.

Regardless of the current pandemic and anticipated global slowdown, the European Commission’s flagship initiative (the European Green Deal) remains a key priority, which aims to “transform the EU into a fair and prosperous society, with a modern, resource-efficient and competitive economy.”

Successful and economically sustainable businesses know that they need to make the investment decisions now to protect their viability in the medium-term.

Responsibility lies with industry to play its part in making the EU carbon neutral by 2050, which includes meeting the interim target of a 55% reduction in carbon dioxide (CO2) emissions by 2030.

The Ecodesign directive is recognised as being the most effective European policy as a way to drive energy savings. The strategy (which includes LOT 31) sets mandatory energy efficiency requirements across a range of products, including compressors.

The “Compressors” product group was identified as a priority in the first iteration of the Ecodesign Working Plan (2009–2011) and all indications point to compressors (ENER Lot 31) being included in the European Commission’s renewal to cover the 2020–2024 period.

This all serves to shine a spotlight (including that of the compressed air industry) on innovation to find new ways of providing quality compressed air and higher levels of sustainability. New technologies and techniques are now coming to the market that allow companies to contain costs without compromising on other critical factors.

Air purity

For a pharmaceutical manufacturing plant, compressed air is an absolute priority. The absence of compressed air will bring a plant to a standstill, much like a lack of power. However, the absence of quality air, which does not meet the global compliance requirements of ISO 8573-1:2010 and ISO 8573-7, can constitute a high contamination and moisture risk.

This could result in drug recalls and export bans, thereby damaging the reputation of the company in question. Throughout these processes, facilities must maintain a zero tolerance approach for impurities. Oil-free screw compressors are the preferred choice as they compress the air inside an oil-free compression chamber, which is effectively sealed to prevent lubrication oil contaminating the compressed air.

Until a few years ago, companies used oil-injected compressors with filtration units that delivered “Class 1” oil quality standards, which means the air must have no more than 0.01 mg/m3 of oil residue. To ensure that no residual oil, airborne particulates or vapour could enter the system, they used downstream air dryers and double line filters to further purify the air.

Today, quality sensitive industries such as drug manufacturing use oil-free air compressors that deliver ISO:8573 (P-2):2007 “Class 0” oil-free air to ensure that 100% contaminant-free air is produced for various applications in their manufacturing and packaging processes.

However, until recently, these compressors were expensive and were used primarily by large companies and those that exported drugs to markets with stringent (US FDA) standards. With the advanced oil-free technology in Class 0-certified compressors, every pharmaceutical manufacturing company can rest assured that their oil-free air not only meets the most stringent standards, they can also benefit from much higher energy savings and uptime.

No oil … water

Compliance and quality are absolute requirements of the pharmaceutical; these criteria push compressor manufacturers to evolve and demonstrate their commitment to compressed air purity of the highest standards. Very often, the pursuit for compressed air purity takes pharma manufacturers to extremes, such as installing multiple filters (instead of one), which increases energy use, increases complexity and results in increased maintenance and costs.

For several years, the pharmaceutical industry has seen water-injected oil-free compressors as a highly efficient alternative to traditional oil-free, dry screw two-stage compressors. They deliver the same Class 0 compressed air in a much simpler, one-stage design whereby water is injected into the air-end — as opposed to oil — thereby cooling it down and sealing the system.

Consequently, the compressor and air-end run at a much lower speed than a dry screw compressor, which translates to increased reliability, lower parts wear, less maintenance and better energy efficiency.

There’s just one “but,” however: most of the water-injected oil-free compressors come with addition technologies such as sensitive reverse osmosis (RO) purifiers in the water inlet line, special rotor materials and complex bearing systems. These systems have proven to be cost-intensive and prone to failure. Today, there is an answer to these issues:

- a closed loop water circuit design with less complexity

- no special bearings or exotic materials

- no need for sensitive RO purifying systems.

In short, there’s an innovative and much more reliable design. For pharmaceutical manufacturing, when failures equal significant losses and wherein reduced power and maintenance costs are critical, the advantages are clear. In this closed-circuit system, the risk of contamination is lowered even further.

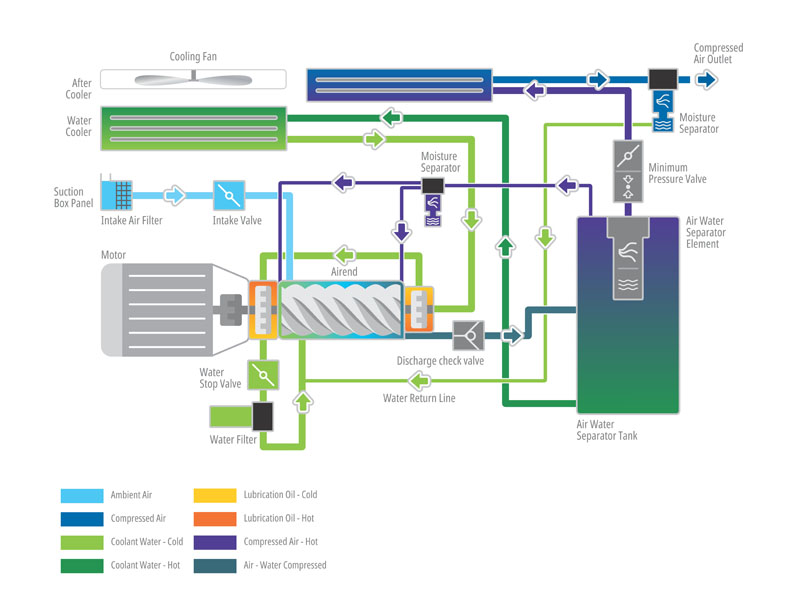

The water is constantly topped up, rinsing and cleaning the insides of the compressor. Furthermore, the compressor drains the condensate wastewater, which, as it’s of drinking water quality, doesn’t require any additional treatment. Finally, in addition to cleaner water and the slower running of the compressor, the closed-loop system can rely on standard, more cost-efficient bearings as used in traditional oil lubricated compressors, reducing complexity and costs further (Figure 1).

Figure 1: How the different components in the compressed air system ensure Class 0 oil-free air

The total cost of ownership of this water-injected compressor is considerably lower (≥8%) compared with traditional two-stage oil-free screw compressors, thanks to the reduced power consumption, the simplicity of the design and ease of maintenance. Compared with oil injected solutions, these systems are even more interesting as the downstream filtration system is less stressed.

Simplicity, efficiency and easier to maintain, the advanced design of these latest closed loop water-injected oil-free compressors can help companies to unlock new avenues of quality in terms of their compressed air needs while also improving equipment uptime (Figure 2).

Figure 2: Example of a closed loop water circuit design with low complexity

All this translates into the energy consumption and reliability costs of a single-stage oil lubricated compressor while providing an oil-free solution. This, in turn, protects pharmaceutical manufacturing processes against more stringent energy efficiency regulations while meeting Class 0 air quality standards — all for a lower total lifecycle cost.