Drives and machine control systems from Omron have allowed UK producer of label die-cutting and finishing equipment, Daco Solutions, to meet converting industry needs for fast and precise changeover between die-cutting options for high-output and lower-output digital print.

As Daco Managing Director Dave Beynon explains, while low-output digital print was the norm, converters would match presses with dedicated semi-rotary die-cutters, typically running at speeds of up to 40m a minute. But with demand growing for digitally-printed labels in pharmaceuticals and other consumer sectors, digital inkjet technology is now printing labels at much higher speeds. In Daco’s case, full rotary die-cutting will run at up to 175m a minute.

'With our new DF350SR system, label converters handling short and long runs can switch between semi-rotary and full rotary mode, with a changeover time of only 10 minutes,' says Beynon. 'By using Omron’s NJ controller, we have produced a powerful and flexible piece of kit, which effectively works as several machines in one.'

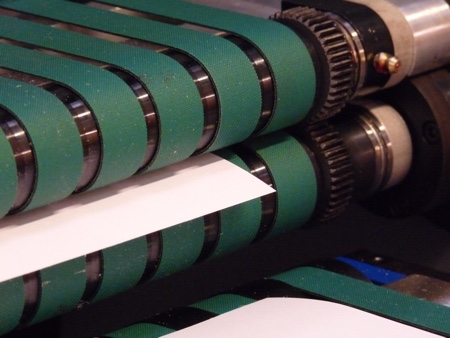

The change in operating principle is necessary because full rotary and semi-rotary die-cutting use completely different types of tooling. Cylinders for full rotary operation are expensive to produce, but the cost is justified by the high volumes of labels being printed. Semi-rotary tooling consists of a magnetic foil, which is cheaper to produce and therefore suitable for shorter run lengths. The foil wraps around the die-cutting cylinder, but unlike the standard cylinder, it is not in register with the label web.

Because the semi-rotary foil covers only a proportion of the cylinder’s surface, the movement of the label web has to adjust. In fact, the web moves forward and then reverses slightly with each turn of the die-cutting cylinder, creating an oscillating movement. The challenge in motion-control terms is to ensure precision in these movements so that each label is accurately cut in register.

The case for using digital print has been strengthened by the requirement, under the EU’s Falsified Medicines Directive, for sequential numbering on each product label

Daco Sales Manager Mark Laurence explains: 'By its very nature, the pharmaceuticals industry tends to require shorter runs of individual labels. Now, the case for using digital print has been strengthened by the requirement, under the EU’s Falsified Medicines Directive, for sequential numbering on each product label.'

As a small company founded 15 years ago, Daco competes most effectively in the niche and bespoke converting machinery segment. This latest semi-rotary die-cutter allows it to take on some of the largest equipment companies in the important – and growing – high-output digital niche.

Omron Field Application Engineer Ian Knight, who worked on the project, says: 'The NJ controller is critical to the success of the machine. Its main function is to synchronise the motion of the web path with the tooling. It has to ensure that the web is pulled back very quickly, but is then perfectly in register with the die-cutting. That adds up to some complex motion control.'

The NJ controller is critical to the success of the machine

As well as the NJ, the DF350SR incorporates three G5 servo drives and Omron’s NB human-machine interface (HMI). 'The HMI is easy to programme, interfaces really neatly with the NJ, and it’s compact, too,' says Beynon.

Daco says it has worked exclusively with Omron for 'anything electrical' in its machines for the past 13 years. 'This means that everything from the HMI to proximity switches comes from a single source,' he says. 'A lot of our machines go to far-flung countries, so we wanted to work with someone who was present all over the world. You’re never far from an Omron integrator or engineer. It’s always the electrics that customers worry about, so that’s been a really good selling point for us.'

Around 90% of Daco’s sales go to export.

Also integrated into the die-cutter is Sysmac Safety. But as Beynon explains, this is not an ‘off-the-peg’ package. 'One benefit of the NJ controller is that some elements of safety are programmable,' he says. 'So, for instance, while in set-up mode, our programming allows the machine to move very slowly with certain guards off. But the built-in safety means that the NJ monitors the speed and shuts down the machine if speeds breach a certain threshold.'

Sysmac Safety allows controlled movement with guards off

Beynon concludes: 'The Omron team were spot-on, getting their head around the concept from the outset, coming up with a list of components (including appropriately-sized servo drives); they did a lot of the maths for us, helped with the wiring, and then worked with our programmer to make it all click together.'