The company uses full spectrum and terp testing, as well as decarboxylation THC/CBD percentages. Their main products include BHO Shatter, BHO Distillate and Rosin. A new, larger warehouse was purchased and they wanted to be completely operational in just a few months.

The challenge

The new facility was large enough to house the small start-up company, all of the equipment needed and room for growth. However, the space they occupy is connected to other suites and nuisance odours could be a concern. Furthermore, the building could not support the installation of the additional ductwork needed for traditional fume hoods. Because the distillate lab would be a converted office space located on the second floor of a shared building, turning it into a lab presented a unique set of challenges:

- find a suitable fume hood, storage solution and air filtration solution to protect the user from inhaling hazardous chemical fumes during a variety of complex chemical processes

- the second-floor location makes transport of large equipment difficult

- with time, the lab’s processes and equipment would change, so they required a fume hood that provided safety, could accommodate the variety of equipment used and would be easy to relocate.

The solution

Erlab was able to provide a Filtration Ecosystem to convert the challenging space into a safe distillate lab and eliminate nuisance odours, both in the lab and throughout the building. The Filtration Ecosystem chosen for their lab is built with the following products that work together to keep the user safe and air in the lab clean:

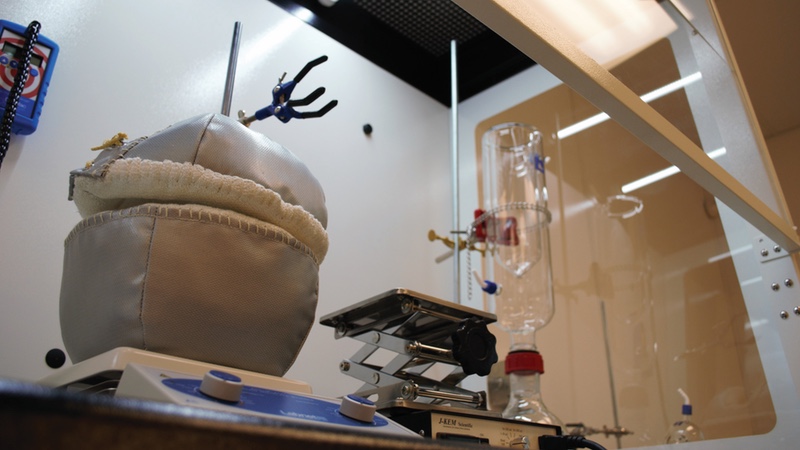

- ductless filtering fume hoods: the chemistry involved is easily handled by Erlab’s filtration technology that keeps users safe while they perform dangerous heating, evaporative and chromatographic work; needing no ducting freed them from limitations and allowed the lab team the flexibility to place (or move) the hoods wherever they needed them

- filtered chemical storage cabinets: the chemicals needed are conveniently stored close to the hood, and Erlab’s filtration technology eliminates exposure to noxious fumes escaping from stock bottles and containers

- Halo air filtration systems: the high volume of chemical processes outside of hoods and throughout the facility meant that air quality could be a concern — not only for them, but also for their neighbouring businesses; with Erlab’s Halos, stray noxious odours and chemical fumes are safely eliminated.

One plus one equals three. By using Erlab’s products together to capture unwanted or hazardous fumes at the source, there is now a safe, clean, flexible and energy efficient lab space — exactly what they wanted.

The result

The upshot of the project was that company’s equipment now easily fits into a converted space and can be disassembled for any future moves or facility upgrades.

The simple set-up meant that the business could be fully operational in a shorter amount of time, reducing construction and operational costs. And, perhaps most importantly, the end users are safe and fully protected from chemical inhalation.