With uniquely challenging conditions required to protect medicinal integrity and exceptionally high value products, this growing therapy class certainly presents hurdles; but, a combination of new technologies and a forward-thinking approach can help to mitigate these.

Unlike traditional broad-spectrum treatments, batch sizes for cell and gene therapies are small — sometimes comprising just a single patient. However, benchtop production methods that work during research and development will not meet regulatory requirements or the efficiency needed for commercialisation.

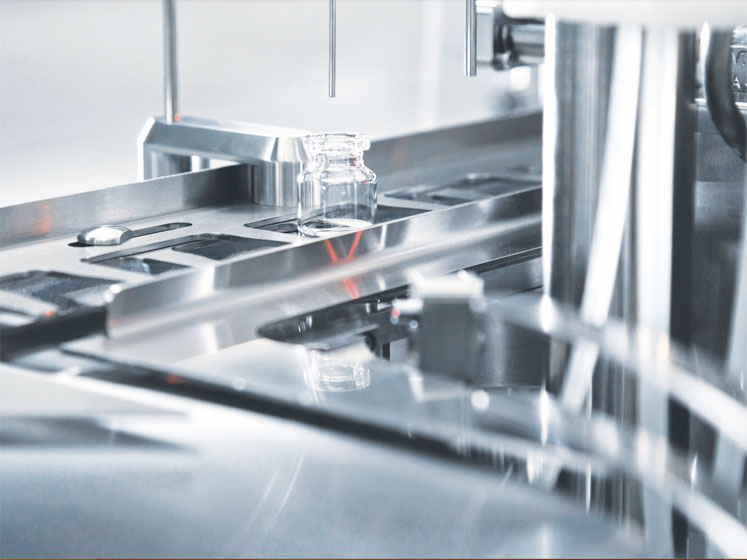

Fill/finish is an important stage to consider to maintain sterility, protect product integrity, meet regulatory requirements and deliver the precise volumes required. What should you prioritise to successfully scale cell and gene therapy fill/finish processes?

And how can you minimise manual involvement, reduce training requirements and deliver high-quality sterile products efficiently?

Risky business: create a robust contamination control strategy

Trace levels of contaminants in a medicine can prove fatal to patients; yet, final product sterilisation methods are incompatible with these biological therapies.1

Contamination is a major risk in cell and gene therapy production; a comprehensive contamination control strategy (CCS) is therefore vital to protect the patient and to avoid the costs and time delays associated with product loss.

It is also necessary to protect operators from potentially hazardous materials during production, so the CCS must be two-way. All containment solutions must control both viable and non-viable contamination. Barrier technologies or the incorporation of presterilised single-use components facilitate this.

“When I think of aseptic processing, I immediately think high risk,” noted Brooke Higgins, a senior policy adviser for global compliance at the US Food and Drug Administration’s (FDA) Center for Drug Evaluation and Research (CDER).2

Human intervention is another key source of contamination, making automation an important tool and bringing added benefits including improved efficiency as well as increased process control and monitoring.

However, it is important that interventions can be made without compromising the aseptic Grade A environment. This can be achieved by incorporating accessibility into process and equipment design.

Playing by the rules: good manufacturing practice (GMP)

Although the US FDA has no plans to enforce the EU’s GMP Annex 1, much of the FDA guidance aligns with this policy and any global organisation will need to comply with international regulations.3

In a recent revision of GMP Annex 1, manufacturers are required to increase contamination control measures, barrier technology and automation to reduce risk to both patients and operators.4

A focused, risk-based approach to protect the critical areas should inform any comprehensive strategy, incorporating the right technology and equipment partners to support the needs and delivery of GMP.

People matter: overcoming a skills shortage

Staff shortages are currently impacting many industries and biopharma is no exception, especially cell and gene therapy manufacturing.5 There is a clear need for increased tuition; however, training is both expensive and time consuming.

Incorporating ease of use and minimised maintenance requirements in process design will offer benefits to all organisations, with process automation reducing staffing burden alongside delivering GMP best practice.

Supply and demand: building a resistant supply chain

The rapid delivery of potentially life-saving treatments to patients in need is always a priority, but it’s also important to redeem the high levels of investment involved in drug development.

Initial facility set-up and the continued supply of single-use components throughout manufacturing requires a reliable and efficient supply chain. Personalised treatments such as cell and gene therapies, may need small, localised production facilities to reach global patients quickly.

These facilities will need to ensure product quality and regulatory compliance, which can be achieved through the incorporation of identical processing lines. Supply partners with a global footprint can meet the demand of both initial hardware and any processing inventory.

Growing pains: choosing products that can scale with you

In the early stages of R&D, manufacturing feels a long way off (sometimes more than a decade away). However, planning ahead is vital to avoid hold-ups down the line.

Organisations should consider processing needs as early as possible, as well as the potential role of contract development manufacturing organisations in future scale-up. Failure to successfully scale-up core processes could lead to failures in large-scale clinical trials that could have been prevented or at least predicted earlier in the process.

To minimise time and cost as scales increase, a partner should be chosen that can support expanding needs using a common technology base. This will create value from initial R&D through to higher volume production.

Using fill/finish as an example, employing benchtop fillers that utilise the same technology as production-scale fill/finish lines in both dispense and single-use fluid path technologies can help to limit the time and cost of validation while ensuring consistent output.

A supplier that can scale with the manufacturing needs of the therapy using common technologies that have been tried, tested and validated reduces the risk as uptake develops.

Collaborating for success

Innovation in R&D needs to be met with innovation in manufacturing to continue to deliver novel treatments to patients on a global scale. This can only be achieved if researchers and manufacturers collaborate to understand current and future processing needs early and ensure that manufacturing doesn’t become the bottleneck.

This will be achieved by engaging with experienced suppliers and partners throughout to deliver the expertise required to support both imminent and long-term goals.

The race is on to become the first to offer curative medicines against a background of growing competition and increasingly complex processing requirements, all with the uncertainty associated with drug development.

Working collaboratively with manufacturing partners who understand the unique demands can only benefit developers and help them to realise the potential of this promising but challenging industry.

References

- www.pharmtech.com/view/contamination-control-for-cell-and-gene-therapies-needs-new-analytics.

- www.raps.org/news-and-articles/news-articles/2023/3/fda-official-warns-manufacturers-of-common-problem.

- www.raps.org/news-and-articles/news-articles/2023/3/regulatory-industry-panels-address-eu-gmp-annex-1.

- www.gmp-compliance.org/gmp-news/finalised-the-revised-eu-annex-1-is-published.

- http://alliancerm.org/wp-content/uploads/2023/03/ARM-Workforce-Gap-Analysis.pdf.