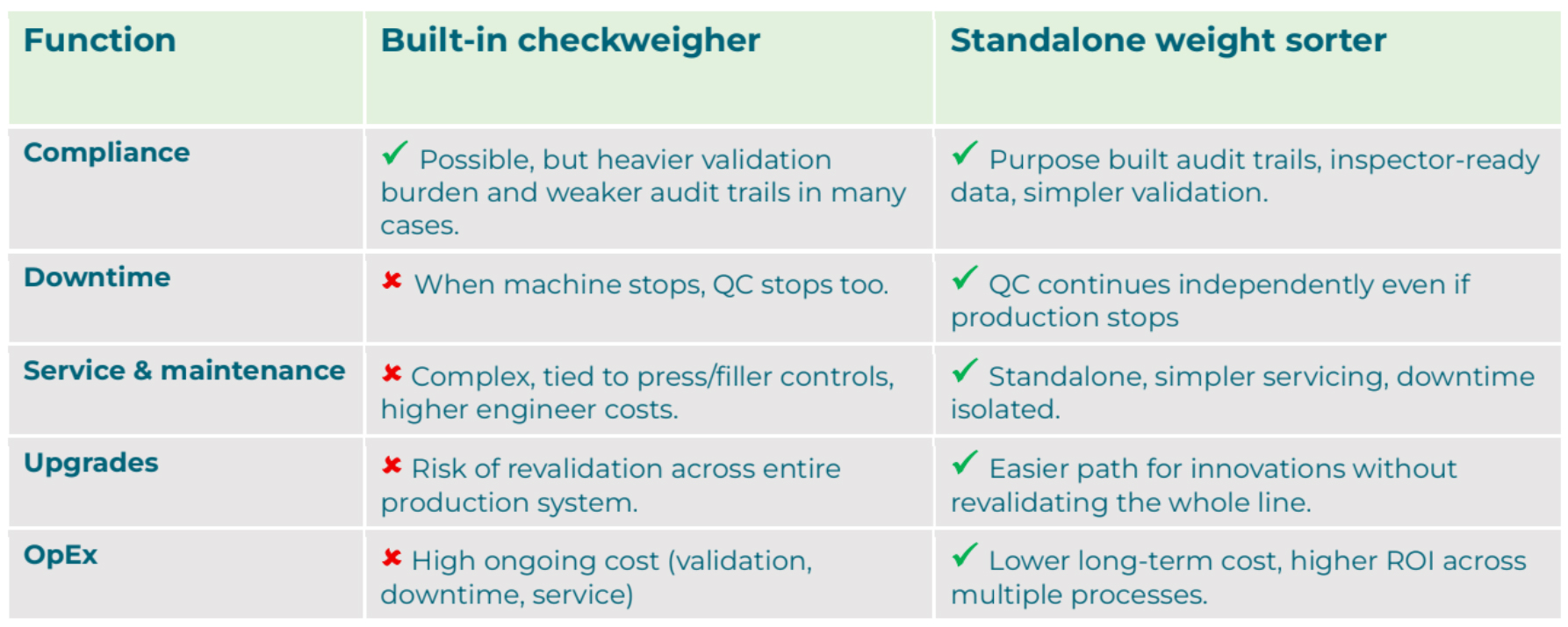

Tablet presses and capsule fillers increasingly promote built-in checkweighing as a convenient, space-saving feature. At first glance, the capital investment looks similar to an independent system — so why add “another” machine?

The difference only becomes clear when you look beyond CapEx and examine total lifecycle cost and risk.

Regulatory & QA Confidence: Standalone

- Purpose-built audit trails: Every action is captured (who, what, when, why), satisfying FDA, MHRA, EU Annex 11, and PIC/S expectations.

- Simpler validation: Standalone SP weight sorters are validated independently, avoiding repeated re-validation whenever press or filler software is updated.

- Data integrity by design: Secure storage, domain authentication, and SCADA/OPC UA connectivity deliver inspector-ready records.

- Independent verification: An impartial record strengthens your defence during audits compared to relying on embedded “black box” outputs.

Operational & Financial Reality: Standalone

- Continuous availability: When a press or filler goes down, its built-in checkweigher goes with it. An SP weight sorter runs independently, keeping QC active.

- One asset, many uses: A single SP weight sorter can serve multiple machines and be deployed for batch recovery, extending ROI across processes.

- Higher yield: ±0.3 mg precision reduces false rejects, ensuring more units make it to market.

- Service & maintenance simplicity: Integrated systems tie servicing to the whole press or filler, raising complexity and cost. Standalone SP weight sorters are quicker and cheaper to maintain — downtime is isolated, not multiplied.

- Future-ready upgrades: Independent systems provide a simpler, lower-risk path to adopt new innovations without triggering revalidation of the production machine’s entire control platform.

- OpEx advantage: When CapEx is similar, ongoing service, validation, downtime, and compliance costs make integrated systems far more expensive in the long run.

Integrated checkweighing may look attractive upfront, but lifecycle reality tells a different story.

Independent SP weight sorters reduce downtime, simplify compliance, and future-proof your operation — all at a lower long-term cost.

If CapEx is the same, why carry the higher OpEx and risk of integrated solutions?

For more information head to www.ciprecision.com