Global regulatory authorities consider CMC to be a prerequisite when reviewing applications. Advanced technologies, adaptable platforms and cutting-edge facilities can all function effectively within a strategic CMC framework.

In the face of the growing complexity and uniqueness of biologic moieties, biopharmaceutical companies compete to develop tailored CMC strategies to advance their molecules to the next stage while maintaining quality.

Kyeyeon Hur, PhD, Senior Director of CMC, and Yunjeong Heo, Senior Scientist, at Samsung Biologics, report.

Consequently, the need to secure the resources required for strategic CMC development is increasing. CMC refers to the comprehensive set of activities required for drug development to meet quality, safety and efficacy standards.

Clinical and operational processes required to advance drugs from discovery to commercialisation — such as upstream and downstream manufacturing, process and formulation development, analytical testing and method validation, process scale-up and technology transfer, stability and shelf-life studies, and control systems for packaging and labelling — all fall under the scope of CMC.

As a desirable practice to meet regulatory requirements, CMC is a dynamic, risk-driven and innovation-led framework that determines whether a drug will progress through development.

The pressure to accelerate development timelines, secure regulatory approvals and ensure sustained commercial supply continues to intensify.

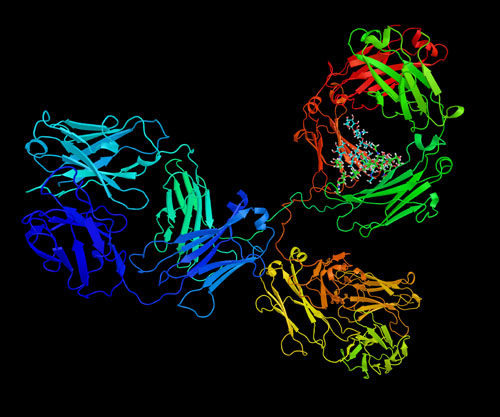

As more complex modalities — such as multispecific and fragmented antibodies, Fc fusions and antibody-drug conjugates (ADCs) — gain prominence, a robust CMC strategy has become a key differentiator.

To address this need, contract development and manufacturing organisations (CDMOs) should provide resources to develop customised CMC strategies to ensure the successful development of molecules.

A tailored CMC strategy comprises analytical development, process characterisation and formulation technology to address the unique stability, potency and delivery challenges of advanced therapeutics.

Therefore, CDMOs are expected to offer execution capabilities as well as strategic/scientific guidance, regulatory foresight and flexible technology platforms that adapt as molecules evolve. This shift in expectations is transforming the contract services landscape.

Companies now favour CDMOs that offer expertise in complex modalities, can customise development packages for smoother approval and expedite technology transfer and scale‑up with flexible infrastructure.

Tailored CMC services also give biopharmaceutical companies real-time insight into process development, quality metrics and risk mitigation strategies to meet their needs for digitalisation and data integrity.

Consequently, leading CDMOs are investing in modular biomanufacturing, AI‑powered analytics and integrated CMC project teams to establish themselves as collaborative innovators in the biopharmaceutical sector.

Customised CMC strategies

To address the growing complexity of drug development, CDMOs must be agile and utilise project experience to assess product quality throughout process development by adopting optimal strategies for programme advancement.

For example, bispecific antibodies (bsAbs) using the widely adopted knob-in-hole (KIH) configuration for correct chain pairing require continuous analytical monitoring to identify potential safety or efficacy issues, such as unwanted aggregates, mispaired antibodies or fragmented products.

BsAbs that target two distinct antigens demand more sophisticated expression systems than traditional monoclonal antibodies (mAbs). This increased complexity makes the development of stable, high-yielding cell lines an ongoing challenge.

Regarding ADCs, the quality of three key components — the antibody backbone, the potent cytotoxic payload and the linker chemistry connecting them — must be reliable. Improving and controlling each element requires advanced characterisation methods and strict compliance with quality standards.

Regulators examine the stability and transport features of the final product to verify safety and effectiveness in clinical or commercial use. As a result, ADC developers need to establish a highly reproducible conjugation process to ensure consistent payload delivery.

Three CMC frameworks

Developing hundreds of CMC strategies to accommodate numerous biologic types in clinical trials and on the market is practically infeasible.

However, establishing a few flexible frameworks that can address diverse molecular structures will enable CDMOs and their clients to advance development projects to approval.

Simplified: The simplified framework harnesses CDMO resources — including accumulated project data, troubleshooting expertise and advanced analytical method development — to address challenges and enable the timely filing of applications for approval.

Central to this framework are readily accessible clinical infrastructures, such as molecule-specific designs of experiment, which accelerate process development and the release testing of molecules.

The outcomes of this framework are data-driven calculations and risk assessments in the planning phase that ensure efficient resource allocation at each stage while minimising waste.

Comprehensive: The comprehensive framework establishes an optimised environment to achieve the desired characterisation of challenging-to-express proteins.

This framework is engineered to improve the quality, efficacy and productivity of the products by leveraging the most suitable development tools to establish a robust manufacturing process.

At its core lies a thorough and detailed testing plan. For example, tailored analytical methods would accurately evaluate the critical quality attributes of molecules during process development to achieve desirable target qualities.

Beyond essential development methods — including host-cell DNA/protein impurity analysis, residual protein A detection, glycan modulation and size/charge variant analysis — additional in‑depth analytical tools, such as HCP identification and sequence variation analysis, can be integrated to enhance product stability and quality by mitigating potential risks.

In-depth analyses during process development and customised characterisation tests are also included in this framework.

In parallel with process development, the framework encompasses methods to screen molecules against surfactants, pH/buffers and other impurities to minimise risk, assess stability and maximise the likelihood of approval.

Lastly, forced degradation and in-use stability studies further enhance the rigour of assessing the unique molecular characteristics identified in earlier stages.

Enhanced: The enhanced framework addresses the distinct requirements of unique biologics throughout all stages of a drug development project and late-phase process redevelopment.

It incorporates problem-solving tools, such as quality-by-design models and science-based analysis, to strategise and overcome both development and regulatory hurdles.

Based on accumulated data-driven knowledge and statistical tools, quality attributes such as the N-glycosylation profile and charge variants can be precisely adjusted during process development to meet the target quality.

In addition, product development that reflects post-commercialisation needs can be achieved. For example, dramatic productivity improvements can be realised by utilising N-1 perfusion for molecules with low-expression cell lines.

Also, using advanced formulation development tools, high-concentration formulations can be developed.

Comprehensive analyses of forced degradation, structure-activity relationships, process characterisation and other pertinent elements help with the analysis of molecular behaviours and the evaluation of the robustness of process development strategies.

Whether the objective is to redesign a cell line, enhance drug purity or reduce the timeline of a technology transfer process, using this framework mitigates the risks associated with drug development projects.

Biologics — whether they are mAbs, bsAbs or ADCs — inherently exhibit unique structures, characteristics and expression patterns, thereby requiring customised approaches for their development.

Beyond considering each molecule’s diversity and complexity, the CMC roadmap should vary depending on the programme development strategy. CDMOs can leverage the three frameworks as a baseline for project-specific CMC strategies that consistently build on a track record of successful development and client outcomes.

Embracing CMC as a strategic business model

In the evolving biopharmaceutical landscape in which complexity is the new norm and accessibility is the next frontier, CMC is the discipline that bridges the gap between vision and execution.

The full potential of CMC unfolds when partnering with the right team addresses development challenges with technically informed communication and expertise backed by experience.

Ultimately, a tailored CMC strategy brings together scientific know-how between drug developers and their CDMO partners, facilitating strategic discussion from the project planning stage.

The CDMOs capable of developing robust CMC strategies will not just survive the competitive race; they will set the pace.