Nuclear magnetic resonance (NMR) spectroscopy is a powerful analytical technique that’s widely used in chemistry, biochemistry and materials science for the identification, structural characterisation and quantification of compounds.

It relies on the interaction between atomic nuclei and magnetic and radiofrequency fields.

Traditional NMR spectrometers use large superconducting magnets to generate very strong magnetic fields to enhance the sensitivity and resolution of the measurement.

However, these high-field instruments can be cost-prohibitive to purchase, run and maintain, and must be operated by specialist technicians.

These instruments are installed in a separate facility because they require a large amount of space and require controlled handling (owing to the use of liquid helium and nitrogen), thereby limiting access and causing delays to sample analysis.

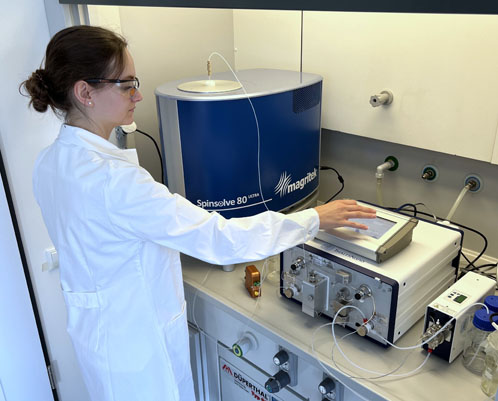

Advances in NMR technology have led to the development of benchtop NMR instruments in recent years, which use compact permanent magnets to generate the required magnetic field.

Their smaller size and the fact that they do not require cryogenic liquids has made it possible for research institutions and laboratories to bring NMR spectroscopy directly to the laboratory bench.

Benchtop systems can also be operated without expert input and provide instant answers to important questions such as: “have we produced the molecule that we need?” This article explores the key benefits of the latest generation of benchtop NMR instruments and their application in reaction analyses.

The role of the solvent

As NMR spectroscopy requires the measurement of samples in solution, and regular solvents have resonances that are orders of magnitude larger than the signal of the products being measured, the standard procedure requires regular solvents to be replaced with deuterated ones.

Sample work-up is a demanding and time-consuming process that requires solvent evaporation and redissolution to be done before each sample can be measured.

Besides eliminating the solvent signal, deuterated solvents have a second and very important function in high-field NMR spectrometers: the signal of deuterium is used to track and correct the drift of the magnetic field generated by the magnet.

By “locking” the magnetic field in this way, the high field stability required for the measurement is achieved.

Magritek’s Spinsolve ULTRA benchtop NMR has a lock system that uses a capillary sample mounted permanently in the magnet. This means that the need for deuterated solvents to lock the magnetic field is eliminated and samples extracted directly from a reactor can be analysed without prior preparation.

However, as these samples are dissolved in protonated solvents with large signals themselves, the spectra of the products being measured can be obscured.

This has led to the development of solvent suppression methods such as PRESAT or WET that only work if the magnets have a high level of homogeneity. Magritek’s Spinsolve ULTRA systems offer ultra-high field homogeneity when combined with solvent suppression.

This makes them capable of measuring compounds dissolved even at submillimolar concentrations in protonated solvents — comparable with compounds that have been dissolved in deuterated solvents.

These important advances in benchtop NMR technology have made it possible for chemistry lab users to reap the many benefits of NMR without the restrictions of the high-field systems.

Application of NMR to reaction monitoring

Chemicals are synthesised in batch or continuous flow reactors. Although these reactors work according to substantially different principles, they both share the need for tools to monitor the progress of the reaction in the batch reactor or to monitor the outcome of a continuous flow reactor.

Benchtop NMR can be applied to the automated analysis of chemical reactions by taking samples at specified intervals and assessing the state of the reaction in real-time.

Is everything running correctly? And do we need to adjust any parameters? Inline reaction monitoring can also be automated and modern benchtop NMR instruments can be hooked up to continuous flow reactors at the production plant or even under fume hoods.

Benchtop NMR machines thus represent a means to automate the analysis of reactions, thereby streamlining workflows and reducing waste.

From theory into practice

Benchtop NMR instruments have been successfully coupled to flow reactors for real-time monitoring in published studies.

In one recent example, Peter Sagmeister et al. used a Magritek Spinsolve ULTRA benchtop NMR to develop a modular platform for the autonomous self-optimisation of reaction systems by using chemometric models to assess rapid-flow NMR and Fourier transform infrared measurements.1

The platform was tested by applying it to a seven-variable, two-step optimisation problem (imine formation and cyclisation for the synthesis of the active pharmaceutical ingredient: edaravone). With only 85 iterations, the platform achieved a solution yield of >95% and minimised reagent excess.

In 2021, The Cronin lab at the University of Glasgow applied benchtop NMR capabilities to power a robotic chemistry discovery system.2 This so called Chemputer was based on a learned association between molecular structures and reactivity and a neural network model.

It was trained using reactivity scores applied to 1H spectra collected using a Magritek Spinsolve 60 benchtop NMR system during 440 reactions between six simple molecules mixed in binary and tertiary combinations under different sets of conditions.

The result: a platform able to assess the reactivity of mixtures regardless of the starting materials; it was then used to discover a new photochemical reaction and a novel reactivity mode for a well-known reagent.

Martin Bornemann-Pfeiffer et al. coupled online NMR with the Chemputer to facilitate autonomous analysis and reaction adjustments.3

The system was tested using Grignard reactions because of their relevance in pharmaceutical and fine chemical synthesis. Real-time NMR monitoring enabled simple feedback control and allowed the Chemputer to alter reaction conditions as needed.

Looking ahead

Benchtop NMR is moving analyses based on NMR spectroscopy out of dedicated facilities and closer to the researchers studying chemical reactions. Benchtop instruments can facilitate important adjustments and improve yields without interrupting the ongoing chemistry.

We expect the power of benchtop NMR systems to increase with further advances in technology … and by NMR developers and users taking advantage of tools such as artificial intelligence and automation.

Could continuous flow reaction monitoring be completely automated in the near future? NMR is well placed to facilitate moves such as this.

Now that benchtop systems are much more suitable for a growing range of important applications, the future will see NMR becoming an indispensable tool in every laboratory as well as in many production scenarios.

References

- P. Sagmeister, et al., Adv. Sci. (Weinh.) 9(10): e2105547 (2022).

- D. Caramelli, et al., ACS Cent. Sci. 7(11), 1821–1830 (2021).

- M. Bornemann-Pfeiffer, et al., Angew. Chem. Int. Ed. Engl. 60(43), 23202–23206 (2021).