The chemical industry’s sustainability journey is often referred to as the “quadruple challenge” or the “double twin transition” comprising a circular and climate-neutral economy, safe and sustainable-by-design chemicals and concurrent digital transition.

Clearly, digitalisation/digital transformation in the chemical industry is not new, with multiple players already applying virtual technologies in their operations. However, enormous opportunities exist for the industry to reach its sustainability goals faster through the application of the latest digital technologies — a journey that is just beginning for most players.

Digital transformation frequently involves IT infrastructure modernisation, more extensive use of data/analytics and the implementation of technologies such as AI, Big Data, the Internet of Things (IoT), robotics, virtual and augmented reality (VR/AR), blockchain and many others.

To understand the digital possibilities and where companies should look to invest, Arthur D Little and Cefic, the European Chemical Industry Council, collaborated on a new report that details how new technologies can accelerate the industry's transformation. This article explores the themes of the report and provides best practice recommendations for successful digitalisation.

Authors Michael Kolk, Managing Partner at Arthur D Little, and Daniel Witthaut, Executive Director of Innovation at Cefic, report.

The types of digital technology that can be deployed

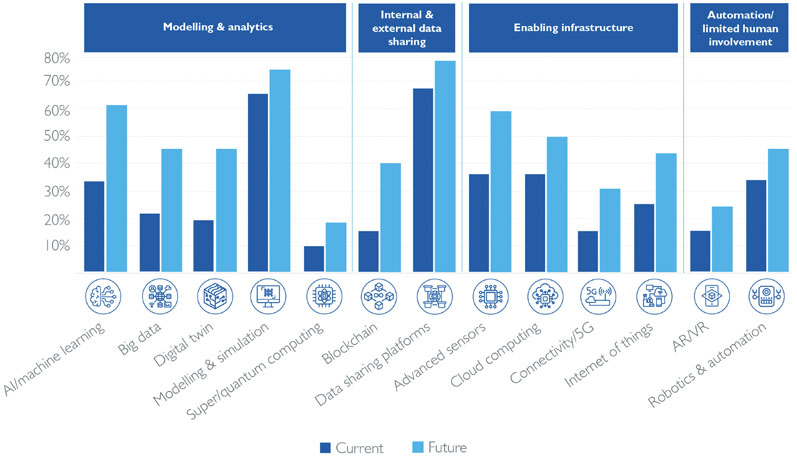

Data-driven digital transformation enables the chemical industry to use a broad range of modern digital technologies to help achieve sustainability goals (Figure 1).

These include modelling and simulation techniques, AI and machine learning, digital twins, robotics and automation, cloud computing, data sharing platforms and blockchain technology, which are already intensively used across the chemical value chain and related ecosystems.

The application of immersive technologies (AR/VR) and IoT integration are now primarily concentrated around production.

Emerging high-performance computational capabilities, such as supercomputing and quantum computing, are currently showing the biggest technological progress towards the digitalisation of research and innovation (R&I), with a potential to perform computationally intensive tasks in other fields such as supply chain optimisation as well.

Figure 1: Digital technologies currently used and planned to be used in the future by chemical companies (%) in the context of the double twin transition

Our survey confirmed that all digital technologies will increase in importance in the coming years and will positively contribute to the sustainable development of the chemical sector, especially AI and machine learning (+82%), Big Data (+110%), digital twins (+130%) and blockchain (+150%), whereas modelling/simulation techniques and data sharing platforms will generally remain the most utilised digital technologies.

The benefits of digitalisation across the chemicals industry

Digital transformation can help to streamline workflows across disciplines, improve operational efficiency, save time and costs, better meet customer expectations and enable companies and industries to become more agile, resilient and sustainable while exploring new business models and revenue streams.

In fact, digital technologies can contribute significantly to many sustainability objectives within the chemicals sector, especially regarding greenhouse gas (GHG) reduction in production, as well as health, safety and environmental targets.

The concept of digitally enabled circularity is also gaining momentum in the chemical industry, with greater focus being placed on energy and feedstock management. Although the chemical industry is already making considerable efforts to apply digital technologies to sustainability in the entire value chain, wider and more intensive implementation will be required to accelerate the double twin transition.

As part of the research, chemical companies were asked where they expected digitisation to have a major impact on their sustainability priorities. The top five areas were as follows.

One: process design and production for climate and circularity objectives

Reaching European Union (EU) climate and circularity objectives calls for disruptive changes in certain types of energy sources (such as green electricity replacing fossil fuels) and feedstock (waste, carbon dioxide [CO2], biobased resources, etc.).

This disruption led 58% of chemical companies to name process design and optimisation in production as the highest sustainability priority to be addressed with digital technologies.

Companies are planning to move beyond conventional data modelling and simulation techniques to exploit Big Data — such as that produced by real-time by sensors. This allows the monitoring of actual production parameters, reveals patterns to help achieve greater energy and resource efficiency, detects production anomalies and improves product quality.

Chemical companies are also adopting AI-supported digital twins fed with current operational data. This enables predictive maintenance and better asset management, reducing downtime while preserving safety and operational efficiency.

Two: sustainability assessment

Meeting climate goals demands systematic evaluation of carbon footprints at product and company levels, including scope 1, 2, and 3 emissions as well as a full evaluation of their existing product portfolio.

The combination of Big Data, data sharing platforms, advanced analytics, modelling and simulation tools help chemical companies to achieve these assessments in two ways.

They improve the availability and transparency of relevant data in the chemical value chain and related ecosystems, and also assist the design and development of new products and processes through advanced modelling and sustainability assessment tools that support decision making from early stage research onwards, including toxicity assessment.

Three: enabling material and chemical circularity

Chemical companies need to consider all aspects of the circular economy throughout the entire product lifecycle, including the feedstock required for the production of chemicals and extending to all subsequent steps until the product’s end-of-life.

Digital technologies are indispensable for tracking and tracing materials and products for circularity, especially with the introduction of the EU’s Digital Product Passport concept.

Circularity will require much broader collaboration to ensure external data sharing. To achieve this, survey respondents are looking to explore blockchain technology as a possible way to share relevant data. However, blockchain technology will not suit every use case, meaning the chemical industry also needs to examine alternative solutions for data sharing in future ecosystems.

Four: sustainable product design

The exploration of product structure-property relationships, greater product safety and sustainability, and improved product performance are key considerations for the chemical industry.

Although laboratory experiments clearly remain a necessity, computer modelling and simulation can complement lab work. In fact, 75% of the surveyed companies that listed product design among their top sustainability priorities already apply advanced computational techniques to better understand what happens during lab experiments and bring to light alternative solutions that may not have been considered.

The adoption of AI and machine learning capabilities further streamlines R&I activities, allowing for faster product design, more effective replacement of hazardous materials, AI-driven predictive toxicology and shorter times to market for new solutions.

Future possibilities include autonomous robotic systems that define and run plausible experiments by themselves while researchers concentrate on other added-value tasks.

Supercomputing and, ultimately, quantum computing, are also expected to bring dramatic benefits to R&I and change the way new products are developed, such as by modelling complex systems such as molecules and polymers with far greater precision.

For example, these technologies enable a search for the most suitable molecular designs or structures to accomplish specific tasks or achieve required effects to be performed in a matter of minutes rather than months.

Five: logistics and distribution

Chemical transport and logistic processes need to meet demanding company-specific and legal requirements on safety, quality and security. Digital solutions can enable secure and accurate data sharing to help reduce operational costs, increase efficiency of resources and foster modal shifts.

Digital solutions may also bring early and proactive risk detection to the supply chain and support rapid interventions, whereas AI-powered solutions can drive smarter, sustainable management by analysing structured and unstructured operational data to deliver more accurate predictions and greater visibility.

The challenges to digital transformation

The chemical industry faces technological, financial, human capital and organisational challenges if it is to successfully embrace digital transformation.

Technology: Digital transformation requires access to relevant data, meaning that it has to be available, interoperable between organisations, standardised and secure. Until recently, however, chemical companies did not value data as a strategic asset; as such, it remained fragmented and difficult to share externally.

Common standards are needed to automate data sharing across the value chain and enable more effective collaboration — all while protecting IP and enforcing cybersecurity standards. All of this has to be underpinned by a modernised and cloud-based IT infrastructure.

Financial investment: Despite a growing understanding of the benefits of digital technologies, securing the required investment still represents the most predominant bottleneck. At least 50% of the surveyed companies hesitate to invest in digital transformation that may not deliver immediate benefits, especially in the current economic situation.

Companies also need to invest in new areas to drive digitalisation, including upgrading legacy systems, platforms and applications, maintenance, restructuring and forming new partnerships with technology providers.

Human capital: Advanced digital skills are in high demand globally and across multiple industries. Currently, approximately 45% of chemical companies find it challenging to attract digital professionals, meaning that the sector needs to be seen as an attractive place to work. Internal skills should be developed, both around digitisation and sustainability, all with limited resources.

Cultures need to change to embrace agility and experimentation for digital transformation to impact the entire organisation, requiring strong change management skills and effective leadership.

Organisational challenges: The chemical industry is in a state of flux, facing current business uncertainties and fast-changing market conditions. This can lead to digital projects not being sufficiently prioritised or funded. Companies need to align their people, structure, activities, processes and culture to achieve organisational goals through digital technologies.

However, preparing for this digital future is no easy task, requiring the synchronisation of both operations and strategy.

Additionally, as in other industries, chemical companies need to balance the need for collaboration with protecting their own IP and ensuring competitiveness. This requires innovative new approaches that, for example, enable data sharing but still put safeguards in place to anonymise or mask confidential information.

Where to start for effective digitalisation

Digital technologies will play an essential enabling role in the transformation of the European chemical industry, enabling it to address the climate, circularity, health, safety and environmental objectives of the European Green Deal.

Several digital technologies are already well implemented, whereas new ones will continue to emerge with high deployment potential in the near future.

Based on the study and our own experience, we believe chemical companies should follow seven key recommendations when it comes to implementing digital technologies to drive sustainable development.

- Explore what can be done collectively: Investigate what is really needed to build scalable solutions for broader and more intensive implementation towards a sustainable future. Explore what can be done collectively within legal boundaries (future-ready data management, interoperability and cybersecurity, required IT infrastructure). Broad collaboration with chemical value chain players and across ecosystems is key to future success.

- Establish common data and technology standards: Standardisation is a prerequisite, as are common data/data sharing and technology protocols that ensure that the industry shares sustainability attributes across the entire value chain and with other market sectors.

- Explore new business models: As the double twin transition comes with major disruptions, the industry needs to explore new (digital) business models and anticipate possible challenges.

- Drive targeted investment: Invest in digital technologies with a view to achieving circularity and sustainability targets.

- Train and attract digital talent: Seek out people with advanced digital skills. Additionally, collaborate with universities to facilitate the development of curricula and educational content that links digitalisation and sustainability within relevant courses.

- Demonstrate best practices: Demonstrate and communicate the benefits of applying digital technologies for sustainability through best practices and actively encourage broader adoption, explaining why improvements need to occur.

- Engage more actively on policy and regulation: Play a more active role in EU digital policies and regulations.